Brake pads

The most famous manufacturers of friction products reasonably believe that the efficiency, reliability and wear resistance of the brake mechanism depend on the quality of its components. One of the most important components of the brake assembly is asbestos-free brake pad which is produced by DAfmi.

Products are made by the method of hot-molding a mixture (in molds with electrical heating). The standard asbestos-free friction mixture, of which brake pads are made on DAfmi, contains 20 or more components. Each of them is responsible for the operation of the brake pad in different loading modes. According to customer reviews, DAfmi pads are reliable in use and take a little time to work on.

They have high mechanical strength, retain their use properties in areas with temperate, tropical and cold climates at temperatures up to minus 60 °C.

Today the range of products of the enterprise is about 500 items of disc and drum brake pads for more than 2000 models of cars produced in Asia, Europe and the CIS. The company’s products are represented by trademarks INTELLI, DTC, DАfmi SM and DАfmi HD.

INTELLI Brake pads

INTELLI are «premium» class brake pads. Their main difference is the use of SAVE DISC TECHNOLOGY (preservation of the brake disc) and NOISE FREE (without noise) technology in their manufacture. In the framework of these technologies, the friction mixture for INTELLI brake pads does not contain steel fibers, but mineral and plant materials.

Stand and road tests showus that thanks to this INTELLI pads allow to reduce brake disc wear by 2–4 times (depending on the type of car and its exploitation conditions) in comparison with metal-containing ones. At the same time INTELLI brake pads are 100% compliant with the requirements for automaker’s friction products in Europe and Asia

INTELLI Brake pads are:- effective slowdown at any speed

- braking comfort: braking noise is reduced, and the plasticity of the friction lining is increased, which, in general, provides better responsetime on the brake pedal

- it will be important for lovers of aesthetics that INTELLI friction pad layer does not leave wear products on the rims.

DAfmi SM brake pads

DAfmi SM brake pads passed full-scale tests on the company’s vehicles, as well as in a number of fleets, where cars are operated in taxi mode successfully, on the dynamometer stand of DAfmi and in the independent laboratory of NAMI (Moscow, Russia).

Also the advanced technology SAVE DISC TECHNOLOGY is used to a lesser extent in the production of DAfmi SM brake pads. Due to this, these products also ensure wear of the brake disc, which is close to the minimum. The term of operation of brake pads meets the requirements of leading manufacturers of elements of brake systems in Japan, Korea and European countries. The force of separation of the brake pad from the base is 4 MPa (at a rate of 2,54 MPa). The coefficient of friction remains stable when heated to 700 °C, and in both dry and wet conditions of operation.

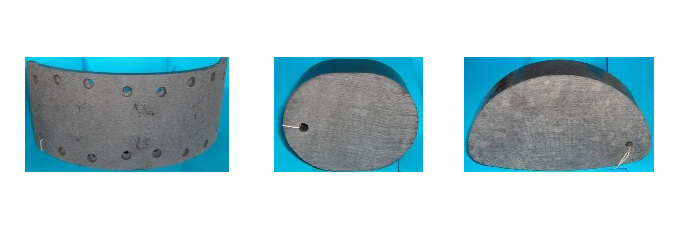

DAfmi SM drum brake pads

The company’s product range includes drum brake pads for the GAZ-3302 Gazel, Moskvich-412, ZiL Bychok 5301, Slavuta, Lanos, Sens and a number of foreign cars.

DTC Brake pads

- safe and effective braking in all weather conditions and driving situations

- stable coefficient of friction during repeated braking

- effective operation over 30 thousand km

- low brake disc wear.

TM DAfmi HD disk brake pads for trucks and semi-trailers

These products are tested by long road tests. The range of DAfmi HD brake pads has only four positions, but their applicability covers the most common trucks in the CIS countries.

DAfmi brake pads for Ust-Katavsky carriage-building plant № 71-631 - six-axle passenger carriage of low floor tram lineup

Brake elements