Specialists of ”DAFMI” LLC test both their products and other manufacturers regularly. Recently they were approached by a representative of a company that sells spare parts, including those manufactured by China. In connection with the fall in sales of brake pads under their brand, he asked to test these products.

The presented set of pads for KIA Cerato has passed a number of standard procedures: measurement of geometry, tests for friction coefficient, wear and tear. In general the products looked and worked ”for their money” as a normal inexpensive Chinese brake pad.

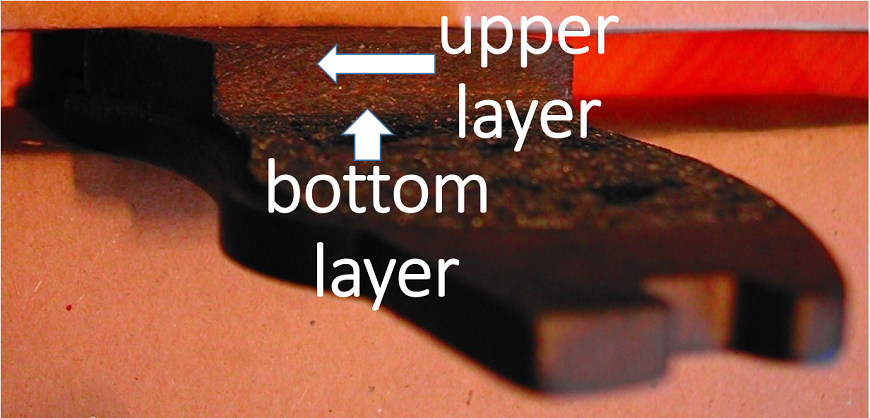

However, the cross section opened the focus. Its friction part consists of two layers. The top layer (thickness is about 3 mm) completed all tests for ”good”. But the bottom one (another 6 mm) proved to be not the best: fast wear of the pad itself and aggressiveness to the disk, the coefficient of friction is extremely unstable. And the reason is that in order to reduce the cost, the composition of this layer included various ”debris” and waste, including abrasive particles from abrasives (formed during polishing pads).

What does it mean for the consumer? Brake pad will work out for the first 2-3 thousand kilometers and then the ”circus” will begin because the pads will wear out quickly, the disc will be erased before our eyes, for braking you will have to push the pedal harder. We keep silent about comfort.

Moral: the consumer does not need to chase for cheapness, the miser pays three times: the first time for cheap pads, the second – for normal, the third – for new wheels.

P.S. The most interesting thing is that the customer of tests was ready for such results, but he did not withdraw this product from sale.